Flooring products play a pivotal role in interior design, as they are typically the first element that catches the eye. Given the substantial square footage that flooring occupies within a home, people are likely to view it repeatedly throughout the day. Having flooring that complements the overall decor can create a calming and relaxing ambiance, while the prospect of faded, water-damaged, scratched, or buckled flooring can be a significant cause of concern for homeowners. In this article, we examine the various factors that contribute to color fading, surface scratching, and plank buckling in flooring products, shedding light on the underlying causes of these common issues.

Floorings material type!

The vinyl flooring market offers a plethora of products, each featuring unique materials that enable end-users to select the ideal option for their specific needs. These materials vary in terms of flexibility and density, with some vinyl flooring products being softer and more pliable while others are denser and harder. Loose-lay vinyl flooring and glue-down vinyl flooring are categorized as soft materials that can be easily bent, whereas SPC core flooring and WPC core flooring products are denser and harder, owing to their distinctive core structures. Soft vinyl flooring products consist mainly of vinyl and plasticizers, while rigid flooring products typically feature composites comprising a lower vinyl content and a higher proportion of mineral powder.

Some common defects in flooring materials!

The type and severity of defects in flooring products can differ, contingent upon the structure of each item. Surface scratches and color fading are among the common defects that can occur, gradually over time due to furniture rubbing against it or suddenly due to sharp objects such as pet paws or toys. Water damage is another potential defect that can affect flooring products. Buckling, as well as mold and mildew growth, are additional defects that will be explored in detail within this article.

Scratches and color fading

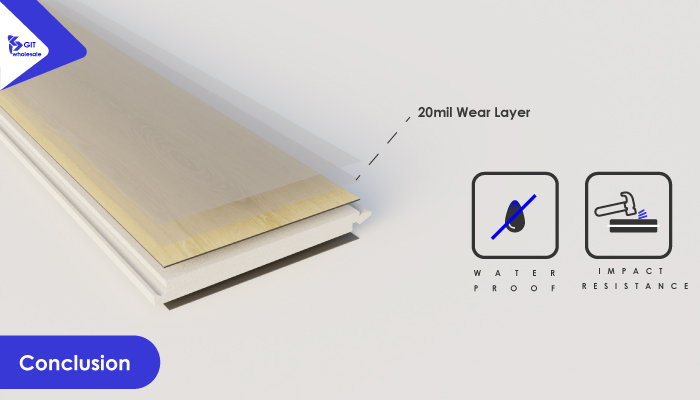

Homeowners frequently encounter issues such as scratches and color fading with their flooring products. Scratches are caused by sharp objects coming into contact with the floor surface, while color fading can result from factors like UV rays or foot traffic in high-use areas. Manufacturers have sought to address these issues by incorporating a wear layer into their flooring products and adding an additional UV protective layer to prevent color fading. The effectiveness and efficiency of the wear layer can differ for various flooring products, but experts recommend that SPC core luxury vinyl plank, with an optimized wear layer thickness of 20 mils, is among the best options available.

Water Damage

Sudden and unforeseeable events like floods or a broken water pipe can cause severe damage to the flooring of a household. Even without these incidents, water seepage from kitchen sources can pose a constant threat to the flooring materials. To address these challenges, SPC core flooring, also known as rigid core luxury vinyl plank, has recently emerged as a promising flooring product that is entirely resistant to water damage. With its ability to repel water, SPC core flooring is an excellent option for homeowners seeking durable and robust flooring solutions.

Buckling is a prevalent anomaly observed in various types of flooring products, which can result in the displacement of the flooring or cracking of the core material. The presence of such defects can significantly compromise the aesthetic appeal and functionality of the flooring, thereby rendering it unsuitable for domestic use. As such, the occurrence of buckling in flooring products is a matter of great concern for homeowners and flooring manufacturers alike. Buckling in flooring materials can be attributed to two primary factors. Firstly, moisture infiltration through the subfloor can lead to swelling and deformation of the flooring material. Secondly, the expansion and contraction of the core of the flooring material in response to temperature changes can also contribute to buckling. These factors can significantly compromise the structural integrity and aesthetic appeal of the flooring, thereby highlighting the importance of selecting appropriate flooring materials that are resistant to buckling.

Conclusion

Understanding the structure of flooring products is essential for identifying defects that may arise in these materials. Several components of flooring products, including the core ingredients, click-lock mechanism, wear layer, and underlay, can all influence the development of defects. An optimized wear layer, for example, can help to protect the flooring from scratches and other types of surface damage. Similarly, choosing the appropriate core ingredient is crucial in safeguarding flooring products against impacts, water penetration, and buckling. Additionally, a reliable click-lock mechanism can protect the flooring from water infiltration, mold and mildew growth, and instability, while a suitable underlay can reduce airborne sound transfer between floors and provide comfortable cushioning underfoot. By considering the role of each of these components in flooring product defects, homeowners and manufacturers can make informed decisions about which materials to choose for their flooring needs. GIT’s SPC core flooring products provide a comprehensive solution to the various challenges that end-users typically encounter with flooring, including resistance to buckling, effective reduction of airborne sound transfer, complete waterproofing, and exceptional impact and scratch resistance. In this article, we aim to provide a more in-depth understanding of the ingredients and components that make up flooring products, with a particular focus on GIT SPC core flooring.

No comment