If you own a home with a beautiful back yard with a swimming pool or a hot tub outside, or if you own an apartment with a nice terrace, or if you are a business owner and would like to let your customers enjoy the fresh air outdoors, you probably need some amenities that will make your property more inviting. They must be made of quality materials and be affordably priced and long-lasting. Decking products can be the best solution to a variety of outdoor projects, but the question is what type of decking product works best for your project?

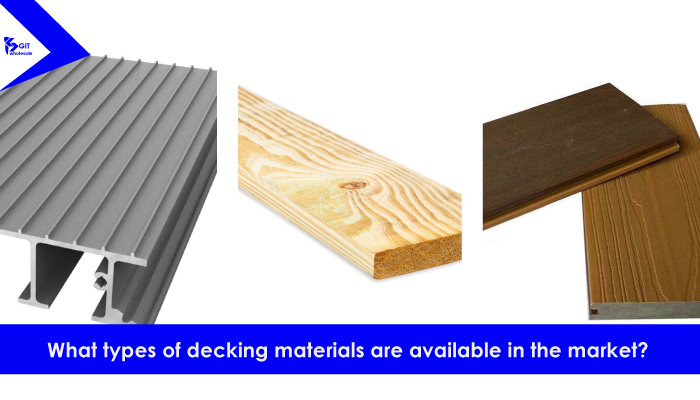

What types of decking materials are available in the market?

Wood Decking

Wood decking is a traditional material that has been used in the construction industry for years. It is made from different types of wood, such as cedar, redwood, and pine. (Link)

Wood decking is a popular choice for homeowners because it is cost-effective, but this material can also be pricy. For instance, the cost of wood decking depends on the type of wood you use and whether or not it has been pressure-treated. Pressure-treated lumber costs more than non-treated boards as it has undergone an additional process that makes it more durable and resistant to rot and decay.

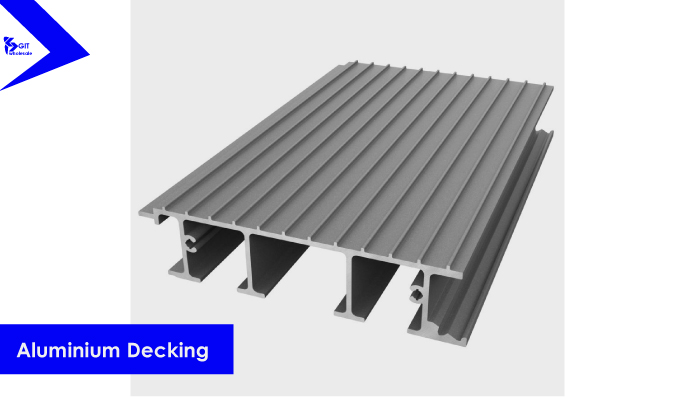

Aluminium Decking

Aluminium Decking is a new decking product in the market, and it is well known for its fire-retardant properties. It is made from aluminium, which is a low-weight material that allows for easy installation and maintenance. It comes in a variety of colours, which gives you more options to choose from when designing your deck. Aluminium Decking product does not rot like wood, it does not splinter like timber, and it is waterproof, so you do not need to paint it every year as you do with timber. You also don’t have to worry about termites eating up your deck because aluminium is termite proof.

Composite Decking

What is Wood Polymer Composite (WPC)?

Wood has been used for construction for thousands of years, providing the materials for houses for doors, walls, decks, and so on. In the last century, as the polymer industries have grown and developed, many wood products have been substituted with plastic materials. Plastic materials were more efficient, and they solved the problems more easily and effectively. However, the fact that pollution from plastics could not be continue led scientist to find a way to mix wood products with polymers to improve their physical properties while saving our planet. One invention was Wood polymer composite (WPC), a combination of a high percentage of wood fiber and a low percentage of a polymer. Manufacturers can use recycled polymer to make Wood Polymer Composite (WPC), and the final product made of WPC can be recycled many times to make new products, so it is environmentally friendly. WPC can be made to be high density, so it is ideal for outdoor products. The tough weather will not have any impact on the physical properties of this material.

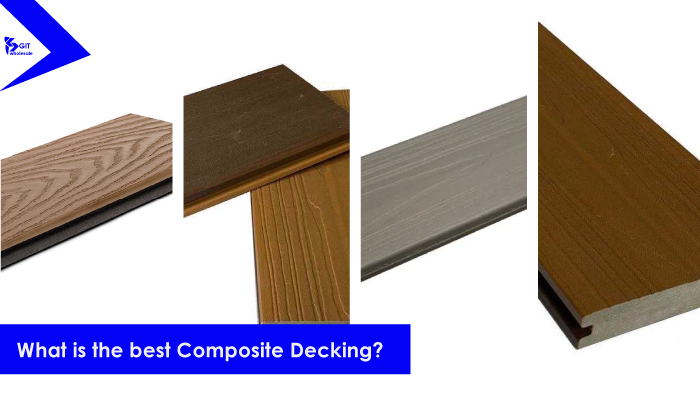

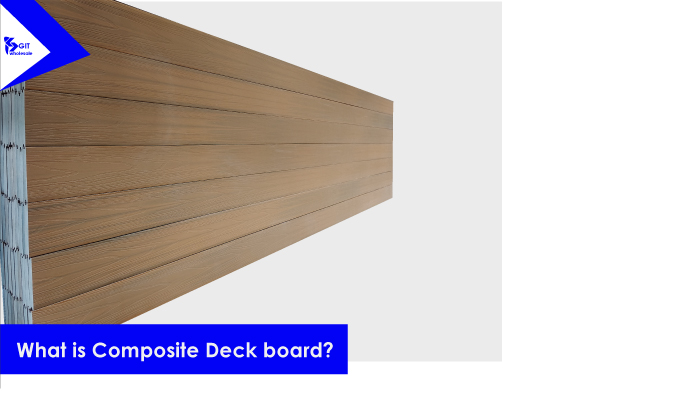

What is Composite Deck board?

Composite decking made of wood polymer composite (WPC) is an ideal material for building decks in backyards, porches, poolside, or on any exterior surface. Composite Deck boards are not susceptible to mold, mildew, or termites. They do not fade in color over time, and they require no regular maintenance. Before purchasing composite decking, it is important to know about the various types of composite decking available so you can make an informed decision. We will describe the most common models below:

Some manufacturers make holes in composite deck boards to vent excess moisture, while others use them to reduce the overall weight of the board. However, some deck installers do not believe that the hollows in deck boards are serving their intended purpose of keeping the board’s strength intact and preventing moisture from reaching the inside. Hollow core composite decks are usually less expensive than other types of decking because their hollowed-out centers reduce the overall weight. Hollows will have no impact on the installation time of composite decks.

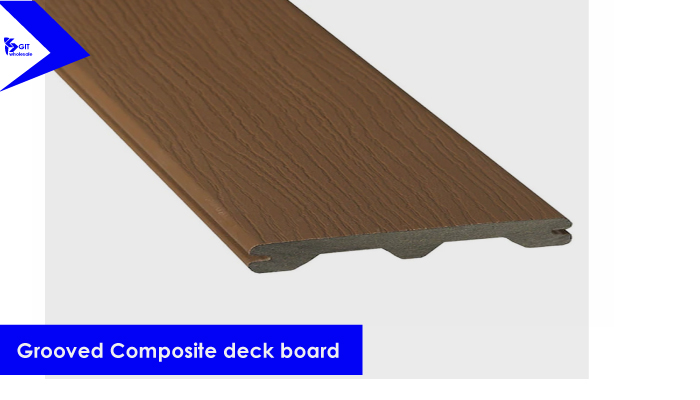

Grooved Composite deck board

The fact that moisture does not affect WPC composite decking to an extent that it would concern homeowners is a positive attribute of the material. Thus, grooved composite deck boards and hollow core composite deck boards are produced to reduce the products’ weight to make transportation easier and to reduce costs. Trex produces a large percentage of the grooved composite deck boards in North America.

Solid Core Composite Deck board

Solid Core Composite Deck Board has no hollow or grooves in its 7/8″ or 1″ core. It is usually heavier than other types of composite deck boards and is expected to be more resistant to weather damage. The most important factor in determining the quality of a solid core composite deck board is its density. The higher the density, the better its functionality will be throughout all seasons.

GIT Composite Deck board is a double-sided color, solid core composite decking product.

GIT Double Sided Color Composite Deck board

It is a solid core board with a high-density core to reduce the risk of shrinkage and warping due to climate change, especially lower temperatures in the winter.

Each side of GIT Composite deck boards have one unique color, and when you flip it around, you will see the different color. A few reasons exist for the push toward double-sided composite board products including reducing the need for additional storage space by retailers, contractors, and installers. Manufacturers often do not want to sell lower quantities of their products, which can be problematic for deck installers and designers who want color options.

The finish of GIT composite deck boards is engineered to repel water, and the color remains vibrant even after years of use.

Clips and Screws

All manufacturers provide their own design clips to attach their composite deck boards to the joists; some are made of plastic, and some are made of stainless steel, and of course, stainless steel clips are more durable than plastic ones. Composite board deck manufacturers may have screws available for purchase, or end-users can ask a hardware store for the appropriate screws.

Conclusion

Outdoor Composite Decking is a valuable addition to any property. Choosing the product that will not fade in color, shrink, or expand due to climate change, and will offer you a wider range of design options to make your investment worthwhile. Although clips used in composite decking installations remain hidden under the boards, the clips’ quality and durability contribute to the overall project’s quality. GIT Composite deck board is designed to play its role to the end-user’s benefit. GIT will never compromise on quality.

No comment